If your Amana dryer is not heating, it likely has either a defective heating element, thermal fuse, high-limit thermostat, or cycling thermostat. If you have a gas dryer, it is likely not heating because of a defective gas valve solenoid. Another possible cause is an incoming power issue, where the dryer is not receiving enough volts to heat properly.

Read on to troubleshoot and fix your Amana dryer.

This guide applies to most Amana dryer models, including the following:

ALE643RBW

CE2402/P7762235W

CE2402/P7762335W

CE4317L2/PCE4317L2

CE4317W2/PCE4317W2

CE8317W2/PCE8317W2

CE8407W/PCE8407W

DLE330RAW

DLG330RAW

LEA30AW

LEA60AW

LGA30AW

LGA60AW

NDE2330AYW

NDE2335AYW

NDE7800AYW

NDG2330AWW

NED4655EW1

NED5100TQ1

NED7200TW10

NED7300WW1

Defective Heating Element

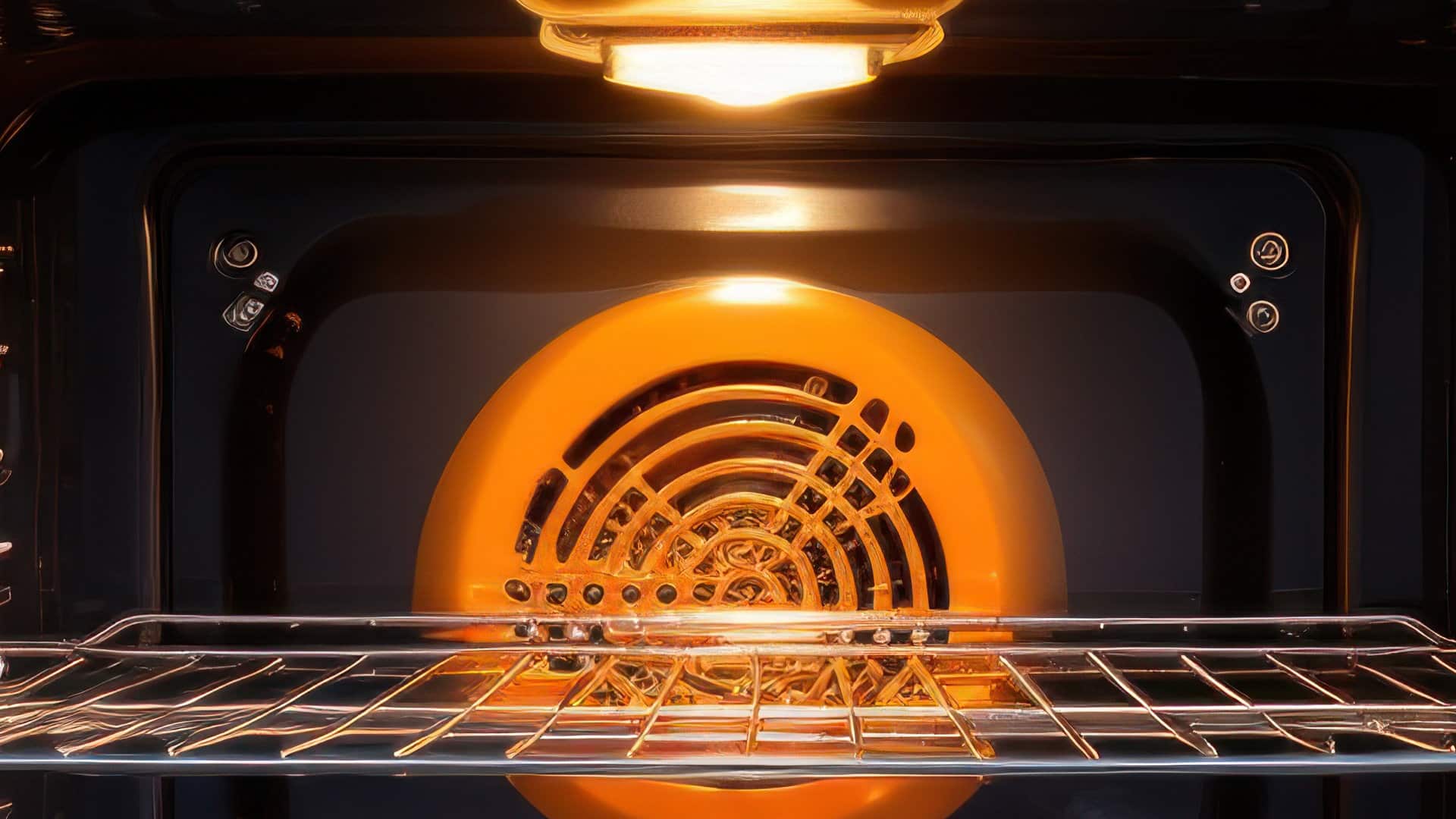

The heating element is responsible for heating the air before it enters the dryer drum. Over time, the heating element can burn out, which means the dryer cannot heat properly.

To diagnose a problem with the heating element, it should be checked for signs of burning or a broken coil, and tested with a multimeter for continuity and ohms of resistance.

The heating element is located at the back of the dryer, inside a metal casing.

Follow these steps to troubleshoot the heating element:

- Disconnect the power to the dryer.

- Unscrew the back panel of the dryer (some models may require removal of the front panel and dryer drum).

- Locate the heating element’s metal casing.

- Disconnect the wiring harness on the heating element casing.

- Use a multimeter to test the heating element terminals for continuity. If there is no continuity, the heating element needs to be replaced.

- Set the multimeter to ohms of resistance and test the heating element terminals again. While readings can vary depending on the model, most dryers should return a reading of around 10 ohms of resistance. If the heating element fails the resistance test, it needs to be replaced.

If you do not have a multimeter, you can check that the heating element coils are not broken and that there are no signs of burning. If a coil is broken, the heating element will need to be replaced. Depending on the severity of the burn marks, the heating element will likely need to be replaced if burn marks are present.

2. Defective Thermal Fuse

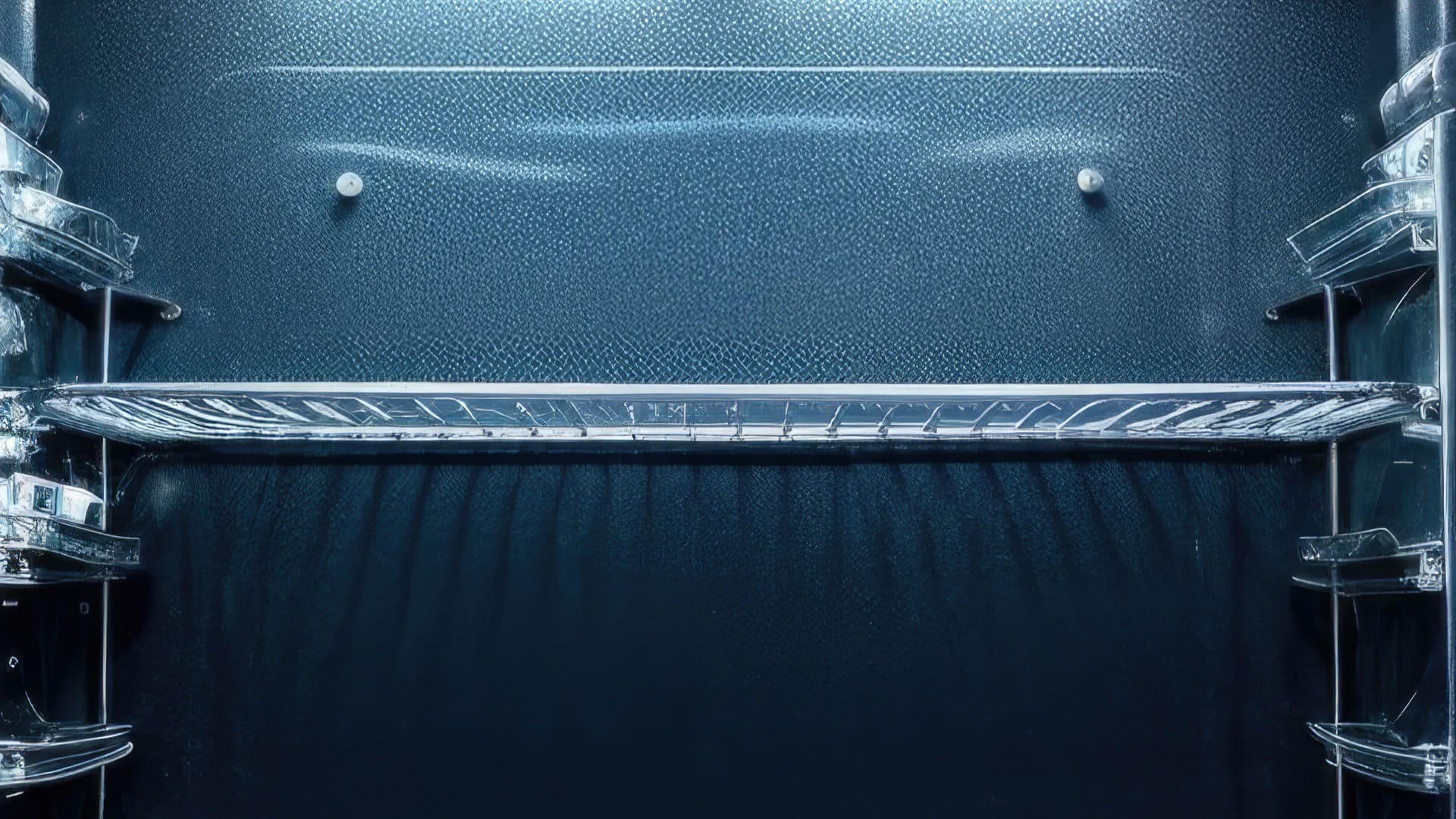

The dryer has a thermal fuse designed to prevent the dryer from overheating. If the dryer becomes too hot, the thermal fuse will blow and the dryer will not heat. A blown thermal fuse cannot be repaired, so it will need to be replaced.

The thermal fuse will need to be tested with a multimeter to determine if it has blown.

The thermal fuse is located at the rear of the dryer, either on the blower housing or close to the heating element casing. The thermal fuse with gas dryers is usually located near the burner.

Follow these steps to check for a blown thermal fuse:

- Disconnect the power to the dryer.

- Unscrew the rear panel of the dryer (some models may require removal of the front panel and dryer drum).

- Locate the thermal fuse.

- Test the thermal fuse for continuity with a multimeter. If the fuse fails the continuity test, it has blown and needs to be replaced.

If you find that the thermal fuse is blown, it is important to find out why it blew. Usually, a thermal fuse will blow because of a buildup of lint that restricts airflow, causing the dryer to overheat. If you have a blown thermal fuse, make sure to check the dryer’s ventilation for a blockage and remove it if you find one.

3. Defective Gas Valve Solenoid

Gas dryers have two or more gas valve solenoid coils, which are responsible for opening the gas valve ports to allow gas into the burner assembly. A defective gas valve solenoid will stop the dryer from heating.

To determine if a solenoid coil has failed, check whether the igniter glows but then shuts off without igniting the flame. If it does not ignite the flame, one or more of the solenoids has likely failed. It is recommended to replace all of the gas valve solenoids as they usually come in a set and it guards against other solenoid coils failing in the near future.

Make sure to disconnect the gas before accessing the gas valve solenoid coils.

4. Defective High-Limit Thermostat

The high-limit thermostat is another component that monitors the temperature in the dryer. If the high-limit thermostat becomes defective, it may falsely tell the dryer’s control board that it is too hot inside the dryer, which stops the dryer from heating.

The high-limit thermostat needs to be tested with a multimeter to determine if it has failed and needs to be replaced.

The high-limit thermostat is located at the rear of the dryer (its exact location varies depending on the model), and will likely require the removal of the dryer’s rear panel (some models require removing the front panel and dryer drum).

Follow these steps to check the high-limit thermostat:

- Disconnect the power to the dryer.

- Remove the relevant access panel (usually the back panel).

- Locate the high-limit thermostat and remove it from the dryer.

- Test the thermostat for continuity with a multimeter. If it does not have continuity, it will need to be replaced.

5. Defective Cycling Thermostat

The cycling thermostat is responsible for turning the heat on and off to regulate the air temperature. A defective cycling thermostat will prevent the dryer from heating correctly.

The cycling thermostat will need to be tested with a multimeter for continuity to determine if it has failed.

Like the high-limit thermostat, the cycling thermostat is located at the rear of the dryer, but its exact location can vary depending on the model of the dryer.

The cycling thermostat will need to be tested with a multimeter to determine if it has failed and needs to be replaced. If the thermostat does not have continuity, replace it with a new one. If it has continuity, you should also check that the thermostat switches off when heat is applied to it.

Follow these steps to check the cycling thermostat:

- Disconnect the power to the dryer.

- Remove the relevant access panel.

- Locate and remove the cycling thermostat from the dryer.

- Test the cycling thermostat for continuity at room temperature. The multimeter probes should touch the outside terminals on the thermostat.

- Apply heat to the thermostat and make sure the thermostat switches off (does not have continuity) when the temperature rises above between 120 and 160 degrees Fahrenheit. The shut-off temperature should be printed on the thermostat.

- If the thermostat still has continuity above its shut-off temperature, it has failed and must be replaced.

6. Incoming power failure

Most Amana dryers require 240 volts of electricity, 120 volts in each leg, to operate properly. If the dryer is not receiving the volts it needs, it will fail to heat the dryer.

The power supply to the dryer can be tested with a multimeter. If the reading is significantly different than 120 volts in each leg, the circuit breaker box should be checked for a breaker that needs to be reset. If you cannot fix the problem, you will need to contact an electrician.

How to Fix the nF Error Code on a Samsung Washer

Kenmore Elite Dryer Issues: How To Troubleshoot

Microwave vs. Oven: Pros and Cons and How They Differ

Self-Cleaning Oven Smell: Causes & Odor Reduction Tips

Frigidaire Ice Maker Not Working? 7 Ways to Fix It

Why Is Your LG Refrigerator Not Cooling? (9 Common Reasons)

GE Oven F2 Error: Causes & Solutions

How to Reset the Water Filter Light on a Samsung Refrigerator

Maytag Washer Showing F5 Error Code? Here’s What To Do