Tales from the Trenches: Fred’s Appliance

Virtual working is only for professions with digital deliverables, right? Designers, coders and writers may be the first people who come to mind, but if you imagine companies that deal in the physical can’t benefit from going virtual, you haven’t talked to Fred’s Appliance.

Virtual working is only for professions with digital deliverables, right? Designers, coders, writers and customer service reps that spend all day on the phone may be the first types of people you think of when you ponder virtual working, but if you think nuts and bolts companies that deal in the physical as well as the digital can’t benefit from new ways of working then you haven’t talked to Fred’s Appliance.

Forget preconceptions of triple copy service tickets and greasy parts rolling around the back of disorganized vans, the Madison, Ohio-based appliance repair company is setting an example in a relatively old-fashioned industry, modeling how more sectors than you might imagine can take advantage of fast connections, cloud computing and a little ingenuity to streamline their businesses.

Talent

Back in 2008, Fred’s Appliance was in trouble. “By January of 2009, we experienced our first layoffs ever,” Adam Butcher, the owner of Fred’s explained in an interview. “The first quarter of that year, we really got ourselves in gear to get paperless.”

The company made some big changes. Rather than have technicians report into the office once a day to pick up their assignments, Fred’s instituted a totally virtual system that has techs skipping the office and heading straight out to customers. “It saves a ton of time, offers better customer service and, of course, it’s a huge cost savings to the company not having the technicians report to a base location each day,” says Butcher, who also notes that the switch saves in fuel costs and wear and tear on vehicles.

Not only did the technicians work more efficiently but so did the small remaining back office staff. “I don’t necessarily want to promote technology to axe jobs, but it kind of worked that way for us. We’re running just about the same amount of service calls that we were prior to 2008 and we have about three less office people,” says Butcher. “We have ten technicians and not including me there are three office people. You’ll find across our industry, it’s usually about a one-to-two ratio. I think we could add two more techs without adding more office staff.”

Tools

So how does Butcher’s team pull this off? A handful of tech tools are key. “We use Google Apps for email, chat and calendar. We also use Vocalocity, which is our phone system. It’s cloud-hosted, which allows us to take our handsets anywhere. OfficeDrop was one of our last legs in becoming truly paperless. Anybody that we’re doing business with, we’re paperless with them if possible, but not all companies are at that level yet, so they are mailing us items that are important. Instead of sticking them in a file cabinet, we scan them and upload them right to OfficeDrop’s cloud,” Butcher says.

Techs in the field all carry stripped down netbooks with touch screen capabilities. Industry specific proprietary software sends their assignments straight to these laptops. “It’s a little piece of software. It’s got a custom drawn map and a job roster list, and we literally drag and drop the service calls. Once the day of the route comes, the technician turns on his laptop and he’s running a little utility that automatically pulls those service calls right in,” Butcher explains. “Through that utility they can capture all the information they need – what they did, model, serial number and they also can bring up a ticket image on the screen. The customer can sign right on the screen. It’s very nifty.”

Dropbox is the final piece of the puzzle. “The technician in the field can document certain things using pictures — a portrait of the unit to show its condition and maybe any pre-existing damage in the house. It also helps with field support. Say you have a newer guy out on the road and he’s looking at a unit he’s not familiar with. He’s able to snap a picture of that and then any supervisor can look at that picture and assist him,” Butcher says.

Tips

The tech know-how needed to patch this system of tools together isn’t vast, but it’s more than many family-owned service companies have on hand, according to Butcher, who is passionate about getting more firms in his industry to work virtually. “When it comes to the technology, for the actual employees themselves, it’s really not that difficult,” Butcher says. “But when it comes to getting a business to this level, you need to have one person that’s tech savvy enough to get the company moving in that direction.”

“I attend a trade show called United Servicers Association each year and put on a class. I push servicers all across the country to get themselves geared up to work in this fashion. There’s a lot of mom and pop. It’s passed down from grandpa and they’re stuck in a lot of the old ways, but they’re realizing that they need to go this direction,” Butcher says, adding, “it’s been a gradual process, but I’d say over the past two to three years, it’s really starting to gain momentum.”

So what tips does Butcher have for small businesses in more traditional industries who are looking to go paperless and virtual like Fred’s? In short, minimize hardware. “Initially we made a very large investment in server space. We actually purchased a rack and servers – very costly. Now we lease cloud space, so we work 100 percent off the cloud-based server and that is one of the best moves that we have ever made,” Butcher says. “Granted the drawback is if you’re having internet interruptions then you’re going to be down, but I feel we have less exposure because all we have to do is drive home and we can work from home.”

And Butcher’s aversion to investing in expensive hardware extends to appliance parts as well. “We have what you could basically call a virtual warehouse. We used to have a ton of parts and it was overtaking our building. That’s another thing we got rid of. We do not have any inventory at our base location at all. The technicians have a small inventory on their trucks for fast-moving parts and then as technicians need parts, they place a parts request with us through the software. We key the order and we ship it directly to the customer’s home.” Usually the part arrives the following day and the repair is completed in two days. The system is quick and also saves in floor space, costly inventory and time spent organizing stock.

“We’re not experts at inventory. We’re experts at service, so why not outsource that expertise to a parts distributor? That’s what they sleep and breathe,” concludes Butcher.

How to Fix the nF Error Code on a Samsung Washer

Kenmore Elite Dryer Issues: How To Troubleshoot

Microwave vs. Oven: Pros and Cons and How They Differ

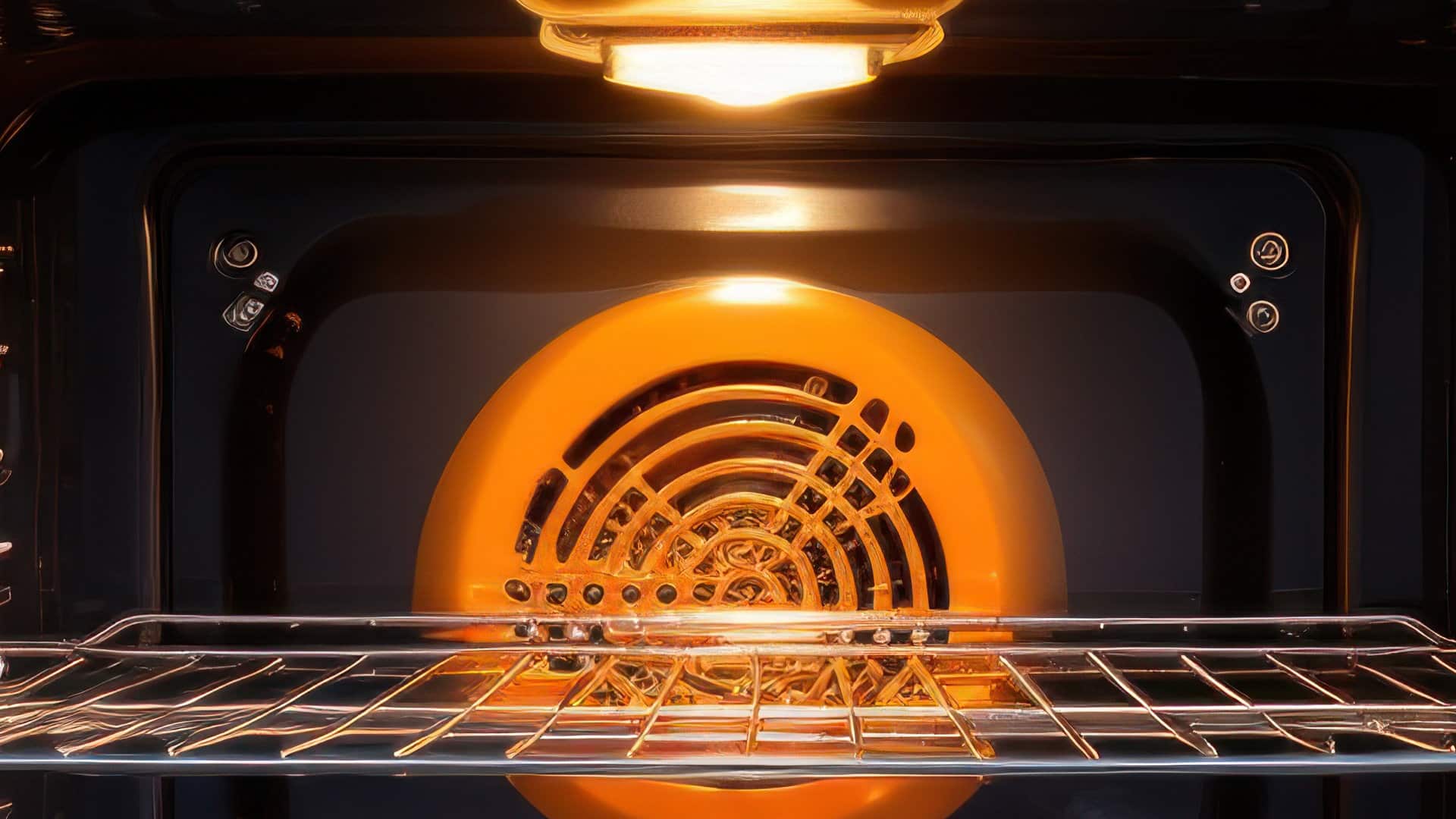

Self-Cleaning Oven Smell: Causes & Odor Reduction Tips

Frigidaire Ice Maker Not Working? 7 Ways to Fix It

Why Is Your LG Refrigerator Not Cooling? (9 Common Reasons)

GE Oven F2 Error: Causes & Solutions

How to Reset the Water Filter Light on a Samsung Refrigerator

Maytag Washer Showing F5 Error Code? Here’s What To Do