Fred's Appliance

April 9, 2018

Washer Repair

Some symptoms of a malfunctioning washing machine are more subtle than others. But the symptom of a washing machine that won’t initiate its spin cycle is usually a wash basket full of water. Yikes!

It could be as simple as the lid switch not actuating, a worn or damaged drive belt, or maybe the transmission decided to give up the ghost during one of the cycles.

The following troubleshooting and repair guide for a defective lid switch can apply to many different brands, however, this guide is specific to the Whirlpool Model LSN1000HQ0.

Defective Lid Switch

The lid switch is a safety device and depending on how your machine is programmed it could activate in one of three ways. When you open or close the lid you should hear the sound of the lid switch activating.

- When the lid is opened some washers have lid switches that stop the washing cycle completely.

- Other models disrupt power during the spin cycle only.

- Some machines allow the washer to fill and agitate while the lid is opened.

If your wash basket is full of water, how are you going to remove it? You could scoop it out by hand with the largest container you can find but that would take the better part of a day and leave you frustrated. We’re as sure as you are that you have better things to do. You wonder if there is an easier way.

Instead of removing the water one bucketful at a time, grab a flat-head screwdriver. Open the lid and with the control set to spin, locate the small rectangular hole located on the top right of the machine. Use the screwdriver to depress and actuate the spin cycle. Your washer will remove the water and if you have any wash in the tub, you can cycle it until the water is removed enough for you to place your wash in the dryer.

Before beginning any work on your washing machine or any appliance for that matter you need to do two things:

- Unplug the washing machine from its power source

- Turn off both hot and cold water valves

It is best to wait for at least 5-minutes before beginning your work. So go have a cup of coffee, read the paper, check your Facebook, Twitter, or Instagram accounts. The reason for the wait is that some electricity remains stored in the capacitor and you could still receive a shock.

How to Remove and Replace the Lid Switch

- Remove the two screws behind the control panel cover

- Lift cover to gain access to the lid switch

- Locate the lid switch to the right and disconnect the wire harness

- Place a multimeter’s leads on the brown and gray wires and check for continuity

- If there is no continuity, you have found your problem. Replace the lid switch

- Locate and remove the two clips that hold the cabinet in place; you will find them to the rear and at the top

- Pull the cabinet from the rear toward the front and remove. It should slip right off

- Now there is clear access to the switch

- Sometimes the brackets that hold the switch in place, break, leaving the lid switch to dangle with no hope of it actuating your machine

- Using a 5/16 nut driver, remove the ground screw that also helps hold the switch in place

- Lift the lid and remove the other screw from the top

- Depress the two tabs that will allow clearance to remove the switch and its harness

- Remove the clips for the wires and pop them out

- Now the switch is free and can be removed

- Replacing the lid switch is a simple as following these instructions in reverse

Defective Drive Belt

The drive belt is what connects the clutch and the transmission. The belt drives the transmission which powers the agitator and the spinning basket. It should be inspected annually.

Does your washer start and then stop? Do you smell burning rubber when your washer is in operation? If your machine is experiencing either of these symptoms, the drive belt could be loose or damaged.

How to Inspect, Tighten, Remove, and Replace a Drive Belt

- Remember Safety First! Unplug the machine from its power source and turn off the hot and cold water.

- Remove the rear panel

- Visually inspect the belt for damage

- If the belt appears to be in good condition, check its tension by depressing the belt mid-way between the two pulleys

- If you can push it further than ½ inch, it is too loose and needs an adjustment

How to Tighten the Drive Belt

- Using a socket and ratchet, loosen the 3 nuts under the motor mount bracket. Do not remove the nuts

- The motor should be loose enough to manipulate

- With one hand pull the motor to the rear and tighten the left nut first

- Tightening the remaining two nuts will increase the tension on the belt. Push on the belt the same way as before to see if it depresses further than the ½ inch recommended tension.

How to Remove and Replace the Drive Belt

- Remove the upper clamp from the coupling

- With socket and ratchet, loosen but don’t remove the 3 nuts on the motor mount bracket

- Push the motor toward the center of the washer

- Remove the old belt and place the new belt into the transmission and clutch pulley grooves

- With one hand, pull the motor to the rear of the washer and tighten the left nut first

- Tighten the remaining two nuts

- Recheck the drive belt tension with the ½ inch test

- Reassemble the pump coupling and clamp

- Reassemble the washing machine, plug it in and do a load of laundry!

Defective Transmission

The transmission generates power from the motor to the agitator and wash basket. It generates both agitation and spin. If the washer appears to be leaking oil, or if the agitation or spin cycles are not working, the transmission needs to be replaced. This particular repair will take some time to complete.

How to Remove and Replace the Transmission

If your washer is equipped with a transmission boot, it will need to be replaced.

Watch this 5-minute video for a detailed tutorial on how to remove the transmission boot, including the removal and replacement of the transmission.

- After the boot is removed, remove the six bolts that anchor the transmission. There are three bolts on either side

- Slide the transmission to the rear of the washer to free the drive belt. Inspect the belt for wear and tear

- Lift the transmission out of the washing basket. Be careful, as the transmission is heavy

- Place one of the bolts in the right rear hole in the new transmission and lower into the washer

- Turn that bolt by hand but not so tight you can’t manipulate the transmission into place

- This one bolt will act as a pivot

- Turn the transmission toward the right rear of the washer

- Reinstall the drive belt in its groove around the transmission pulley

- Realign transmission to the remaining holes

- Replace and tighten the five remaining bolts

- Refer to the previous video to complete the assembly

We hope this has helped explain some of the more simple repairs for a washing machine that has stopped spinning or agitating. But we understand that not everyone has the time or is cut out for do-it-yourself projects and need to find a company who does. Someone who is an expert in appliance repair. Do you have something else you’d like to discuss? Reach out to us today and we’ll reach right back to you.

888-453-7337Text or ring! ring!

Live ChatClick to say hi

Apr. 09, 2024

How to Fix the nF Error Code on a Samsung Washer

Apr. 09, 2024

Kenmore Elite Dryer Issues: How To Troubleshoot

Mar. 06, 2024

Microwave vs. Oven: Pros and Cons and How They Differ

Mar. 06, 2024

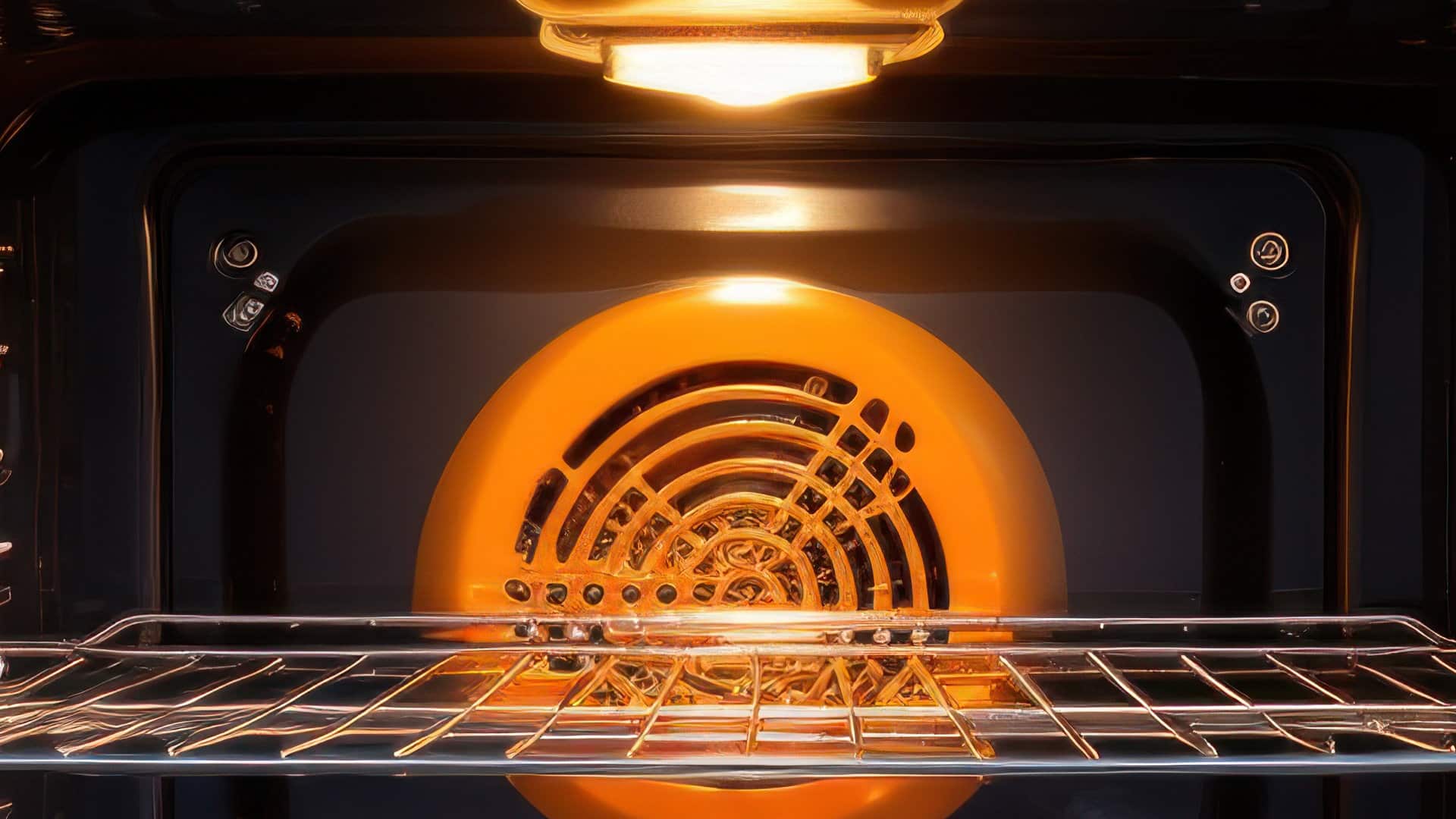

Self-Cleaning Oven Smell: Causes & Odor Reduction Tips

Mar. 06, 2024

Frigidaire Ice Maker Not Working? 7 Ways to Fix It

Feb. 05, 2024

Why Is Your LG Refrigerator Not Cooling? (9 Common Reasons)

Feb. 05, 2024

GE Oven F2 Error: Causes & Solutions

Jan. 03, 2024

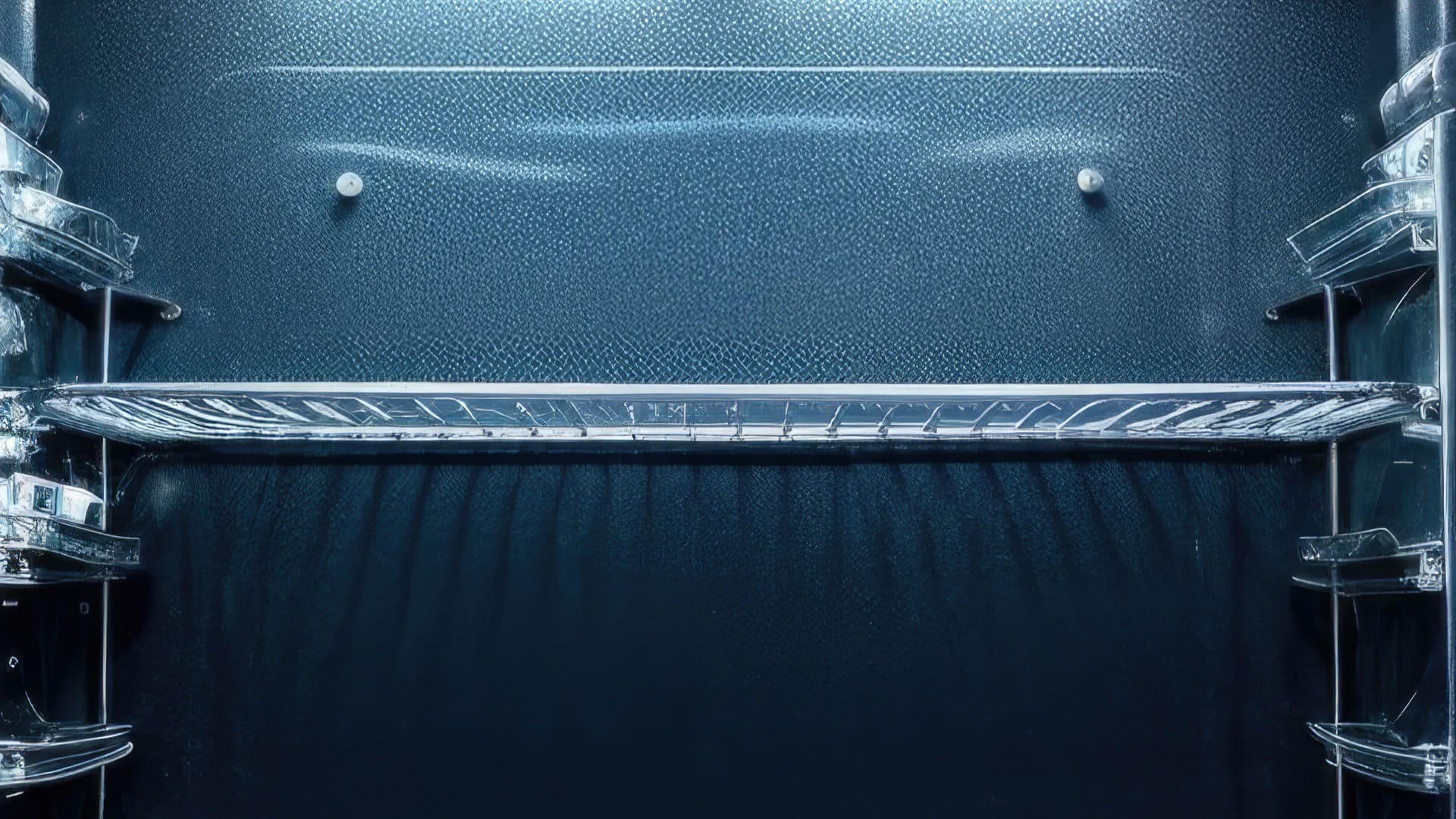

How to Reset the Water Filter Light on a Samsung Refrigerator

Jan. 03, 2024

Maytag Washer Showing F5 Error Code? Here’s What To Do

Jan. 03, 2024